Friday, November 23, 2018

Altium Designer: Useful Shortcuts for Component Placement

- Rotate counterclockwise by 90 degrees while moving an object : SPACEBAR

- Align selected objects by top edges : SHIFT + CTRL + T

- Distribute selected objects equally in horizontal plane : SHIFT + CTRL + H

- Align selected objects by left edges : SHIFT + CTRL + L

- Align selected objects by right edges : SHIFT + CTRL + R

- Distribute selected objects equally in vertical plane : SHIFT + CTRL + V

- Align selected objects to grid : SHIFT + CTRL + D

- Align selected objects by bottom edges : SHIFT + CTRL + B

Thursday, November 22, 2018

Altium Designer : Pcb Panelization

On the Place tab, Select Embedded Board Array/ Panelize. Click anywhere in the PCB area. Under Properties menu, select your PCB and set desired Column margin and Row spacing.

Altium Designer : Creating Board Outline From Mechanical Outline and Making Cutout Holes

Select Mechanical Outline. Under Properties menu, Change Mechanical outline layer to user defined board outline layer.

To create custom board shape, select board outline that has been created. On the Design Tab, in the board shape, select Define from selected Objects.

To create a cutout hole, select the desired outline. On the Tool Tab, in the Convert, select Create Boardcutout from selected primitives.

Altium Designer, Shortcuts for Viewing, Changing Grid and Snap Setting

Toggle measurement Unit : Q

Accessing Grid menu : G

Changing snap setting : SHIFT + E

Switching 2D and 3 D View : 2 & 3

Fit all objects into view : CTRL + PAGE DOWN

Zoom in around cursor (zooms around cursor, position the cursor first) : CTRL + Mouse-wheel up (or PAGE UP)

Zoom out : CTRL + Mouse-wheel down (or PAGE DOWN)

Wednesday, November 21, 2018

AAA Battery Protection with Wrong Polarity LED Indicator

This simple circuit will protect AA or AAA battery from wrong polarity connection to your device. If the battery is connected in opposite way, D1 will conduct and PTC Fuse will break the circuit. Wrong polarity indicator, LED 1 will be turned on at the same time.

Thursday, June 7, 2018

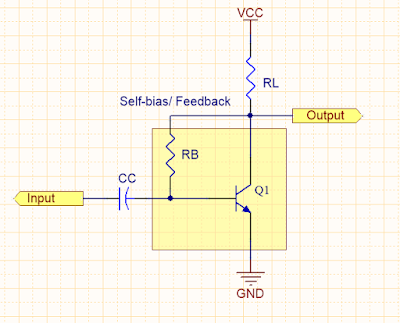

A Basic Transistor Amplifier with self-bias

This circuit will amplified the input signal with self-bias or feedback which can prevent amplitude distortion. However, it has two small drawbacks. It is only partially effective and, therefore, is only used where moderate changes in ambient temperature are expected.It reduces amplification since the signal on the collector also effects the base voltage. This is because the collector and base signals for this particular amplifier configuration are 180 degrees out of phase (opposite in polarity) and the part of the collector signal that is fed back to the base cancels some of the input signal. This process of returning a part of the output back to its input is known as DEGENERATION or NEGATIVE FEEDBACK. Sometimes degeneration is desired to prevent amplitude distortion (an output signal that fails to follow the input exactly) and self-bias may be used for this purpose.

Wednesday, June 6, 2018

Common Mode and Differential Mode Filters to limit EMI Issues

This EMI filter include common-mode filter and differential mode filter. Generally Differential mode filter filters noise less than 30MHz and Common mode filter filers noise from 30 MHz to 100 MHz. Both filter have an effect on the entire frequency where EMI needs limiting.

Thursday, May 24, 2018

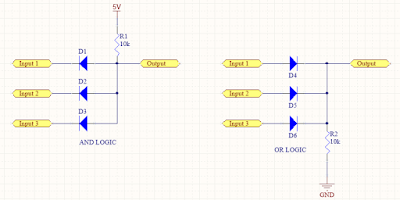

Simple Logic Gates using Diodes

Diodes can be used for implementing simple logic gates such as AND or OR combinations. For AND gate, all inputs must be tie to high, 5V for the output logic high. For OR gate, the output is high if any input(s) are high.

Thursday, May 10, 2018

Emergency Phone Charger From 3 x AA Battery with output Protection

Three AA batteries (3 x 1.5V) is using as emergency power source for mobile device or phone charging. Output current is limited to 0.5A and protected from out short circuit or high current drawn from the batteries.

Saturday, April 21, 2018

Guidelines for the design and layout of high-speed digital logic PCBs

- Give a lot of consideration to component placement and orientation

- Avoid overlapping clock harmonics. Make harmonic table for each clock

- Clock signal loop area must be kept as small as possible. Get paranoid about clocks.

- Use multilayer boards with power and ground planes whenever possible.

- All high frequency signal traces must be on layers adjacent to a plane

- Keep signal layers as close to the adjacent plane layer as possible (<10 mils)

- Above 25MHz PCBs should have two or more ground planes

- When power and ground planes are on adjacent layers, the power plane should be recessed from the edge of the ground plane by a distance equal to 20 times the spacing between the planes

- Bury clock signals between power and ground planes whenever possible.

- Avoid slot in ground plane. Also applies to power plane.

- If a segmented power plane is necessary, signal traces must not be routed over the slots.

- Filter (series terminate) the output of clock drivers to slow down their rise/fall times and to reduce ringing typically 33 to 70 ohms

- Place the clock & high speed circuitry as far away from I/O area as possible.

- Use a minimum of two equal values decoupling capacitor on DIP packages, four on square packages. On high frequency/ high power/noisy IC many more capacitors may be necessary

- Consider using embedded capacitance PCB structure for decoupling on h-f boards (>50 MHz)

- Use impedance-controlled PCB layout technique with proper terminations where necessary

- On impedance-controlled PCB, do not transitions the signal from one layer to another unless both layers are referenced to the same plane

- On non-impedance-controlled PCBs, when a clock transitions from one layer to another & the layers are referenced to different planes add a transfer via or capacitor between the planes

- All traces whose length (in inches) is equal to or greater than the signal rise/fall time (in nanoseconds) must have provision for a series-termination resistor (typically 33 ohms)

- Simulate all nets whose length (in inches) is equal to or greater than the signal rise/fall time (in ns)

- Connect logic ground to the chassis (with a very low Z connection) in the I/O area. This is crucial!

- Provide for an additional ground to chassis connection at the clock/oscillator location.

- Additional ground to chassis connection may also be required

- Daughter boards (with h-f, noisy devices and/or external cables) must be properly grounded to the motherboard and/or chassis (do not rely the ground pin s in the connector to provide this ground)

- Provide C-M filters on all I/O lines. Group all I/O lines together in a designated I/O area of PCB

- Shunt capacitors used in I/O filters must have a very low impedance connection to chassis.

- Use a power entry filter on the dc power line (both C-M and D-M)

- Most products in plastic enclosures need to be provided with an additional metal reference plane

- Consider the use of board level component shields where applicable

- Ground all heat sinks

Subscribe to:

Posts (Atom)

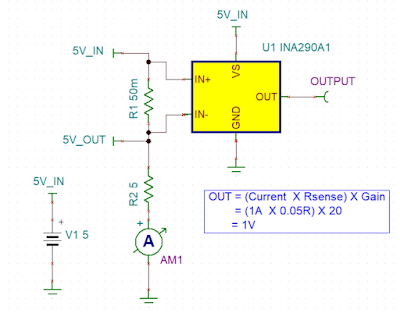

Ultra-Precise, Current-Sense Amplifier

This ultra-precise current sense amplifier that can measure voltage drops across shunt resistor, R1 over a wide common mode range from 2....

-

Voltage divider resistor network is used to step monitored voltage down to the range as necessary for A/D conversion. Passive low-pass f...

-

Import Changes from Schematics to PCB in Alitum as below. 1) Compile the Project 2) Design >> Import Changes From XXX.PrjPCB 3)Execut...